Spectroscopy

Spectroscopy in a broad sense is the study of the interaction between radiation and matter as a function of wavelength. CAPPA’s spectroscopic platform is primarily based on Fourier Transform Infrared (FTIR) and Raman spectroscopy techniques and its capabilities cover the spectral range from the ultraviolet, through the visible, near IR and mid IR and beyond to the Terahertz region. FT-IR measurements at all wavelengths can also be carried out with an evacuated optics bench that can eliminate atmospheric moisture absorptions for ultimate sensitivity and stability. In addition to traditional spectroscopy, CAPPA also engages in both Photo-reflectance and Photoluminescence Dynamics Spectroscopy as well as two colour Pump-Probe Spectroscopy.

CAPPA’s Terahertz capabilities can provide unique spectroscopic signatures not found at other wavelengths and can resolve many of the questions left unanswered by complementary techniques, such as optical imaging, Raman and Infrared. Many common materials and living tissues are semi-transparent to Terahertz light which as a result presents exciting opportunities not available in traditional near-IR spectroscopy.

In addition to the FTIR and Raman spectroscopy, CAPPA also carries out energy dispersive spectroscopy (EDS) which measures the number of x-rays produced by a solid sample when irradiated by electrons versus the energy of these x-rays. The EDS technique identifies and quantifies the elemental constituents of the sample under test.

CAPPA has a wide variety of capabilities in spectroscopy applications. These include but are not limited to structural changes in materials, fluorescence detection, time – dependent change analysis, raw ingredient characterization, failure mechanism exploration, polymer analysis and hyperspectral imaging.

Fluorescence Detection

Unlike Raman and IR spectroscopy, which are instantaneous, fluorescence has a temporal profile to add to spectral, revealing more information. Fluorescence is regularly used to identify the presence of oxygen in a sample, exploiting its fluorescence quenching properties. Fluorescence is regularly employed with a marker, enhancing its signal, enabling sub-surface investigations. This approach is used regularly in biological sub-tissue applications.

Partner company Luxcel Biosciences produce a set of low – cost materials whose fluorescent lifetimes respond to the gas concentration in their environment, CAPPA developed a hand – held sensor module which can illuminate their oxygen – sensitive material and collect the time – resolved fluorescent signal, complete with a user interface for calibration and data management. This enables the fluorescent material to be placed inside transparent packaging of food, medical device, or pharmaceutical products, and to interrogate the oxygen concentration within the package from outside.

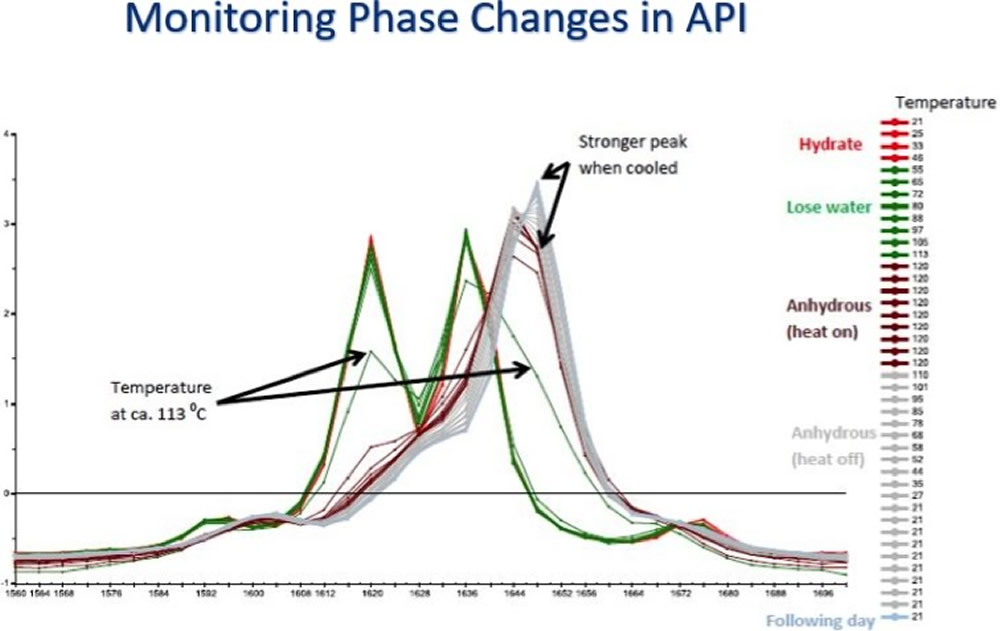

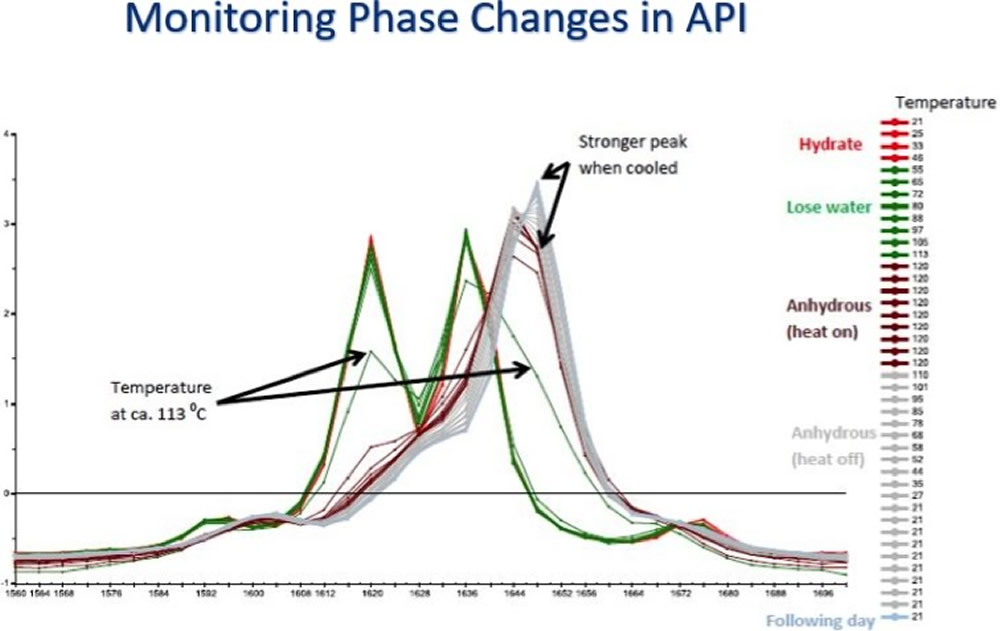

Time-Dependent Change Analysis

Scheduling of production of materials with a limited shelf life, during either initial production, packaging or final-end-use, is crucial for companies. The non-destructive character of optical spectroscopy enables monitoring the same sample through each phase of production, identifying areas where temporal optimization can have significant benefit. API and support matrix variations are continually characterized at CAPPA.

Real Time Solid Powder Drug Dose Measurement and Structural Changes in Materials

Studies of material variation in production are usually on the timescale of several hours, days or weeks. However, the instantaneous interaction of light with material enables the monitoring at a much shorter timescale. E.g., material flowing from a dry powder inhaler rapidly interact on a microsecond timeframe, by different forms of agglomeration. Absorption and scattering of light at different positions, or times, in the flow can be used to identify the rate of agglomeration and the size of the particles formed. Varying structural order in materials have strong Raman and Infrared fingerprints. Identifying the degree of crystallinity to amorphous structure is pertinent in API and medical samples.

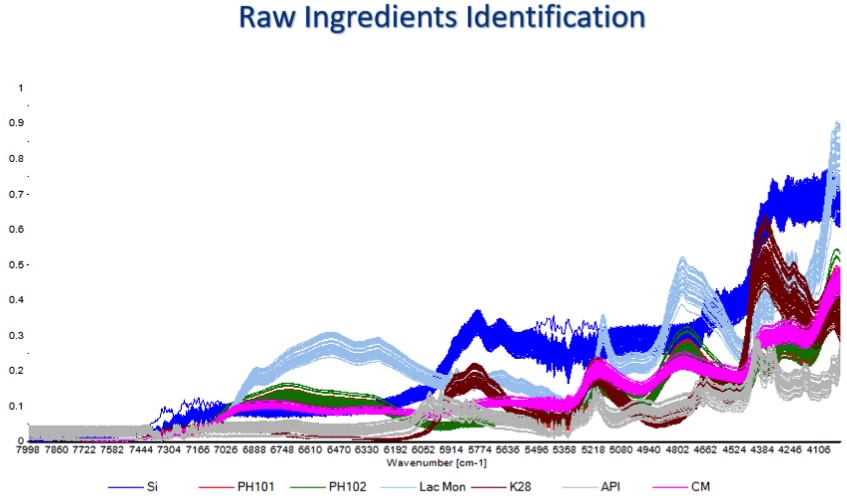

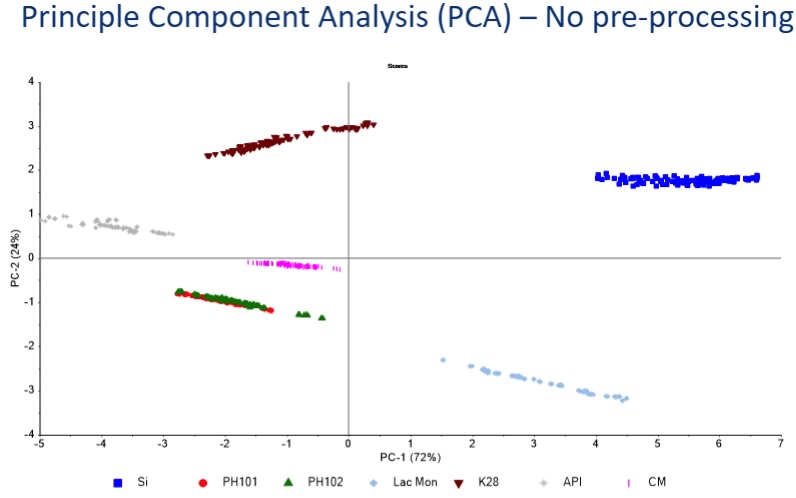

Raw Ingredient Characterization

Classification of raw ingredients is crucial in sustaining conformity during production and consistency required in delivery dockets. The spectroscopic fingerprint of characterised ingredients can be monitored throughout production, identifying variation in the ingredient or contaminant. Raw ingredient characterisation can lead to reduced material movement and handling, improved quality control of both raw and final products and higher throughput by avoiding laboratory testing delays. Finally, raw ingredient characterisation can also serve as a means to ensure standardisation of materials from one lot of final products to the next, thus developing a better understanding of raw materials for delivering superior products of the finest quality.

Failure Mechanism Exploration

The failure of different components of machinery can leave a characteristic material in the sample, atmosphere or on the machinery itself, which if identified at the starting point can identify the complication before it occurs. CAPPA employs are a range of methods with an array of advantages, such as identification of organic functional groups, high magnification (300,000X) with a large depth of focus for magnifying abnormalities and rapid x-ray spectra of atomic elements can be analysed simultaneously. CAPPA’s accomplished consultation with industrial partners have identified such markers and enable CAPPA to construct detection techniques for machine malfunction.

Polymer Analysis

Raman, IR and Hyperspectral imaging of polymer compounds can recover information on production processes, such as temperature and moisture intrusion, compatibility of samples and can be practised on application specific tracking.

Polymers find use in almost every aspect of our day-to-day lives. Food, cosmetics and drug packaging, medical devices and consumer electronics are only a few examples of the everyday things that contain polymers. Spectroscopic techniques are routinely applied in a range of analytical tasks related to polymers, for example, identification, quality testing, composition analysis, detection of adulterants etc. The flexibility of spectroscopy as a tool for polymer analysis may be demonstrated by its application in diverse areas of quality testing. Examples include moisture content testing in recycled polymers and molecular chain length measurement in polymers used in the manufacture of medical devices. Multivariate analysis techniques may be combined with spectroscopic data to identify trends and clusters in data taken from multiple samples. This may reveal critical information relating to how the parameters of a given processing method effect the polymer. Whatever the polymer, it is likely that the spectroscopic techniques available at CAPPA can reveal something new about your materials and processes.

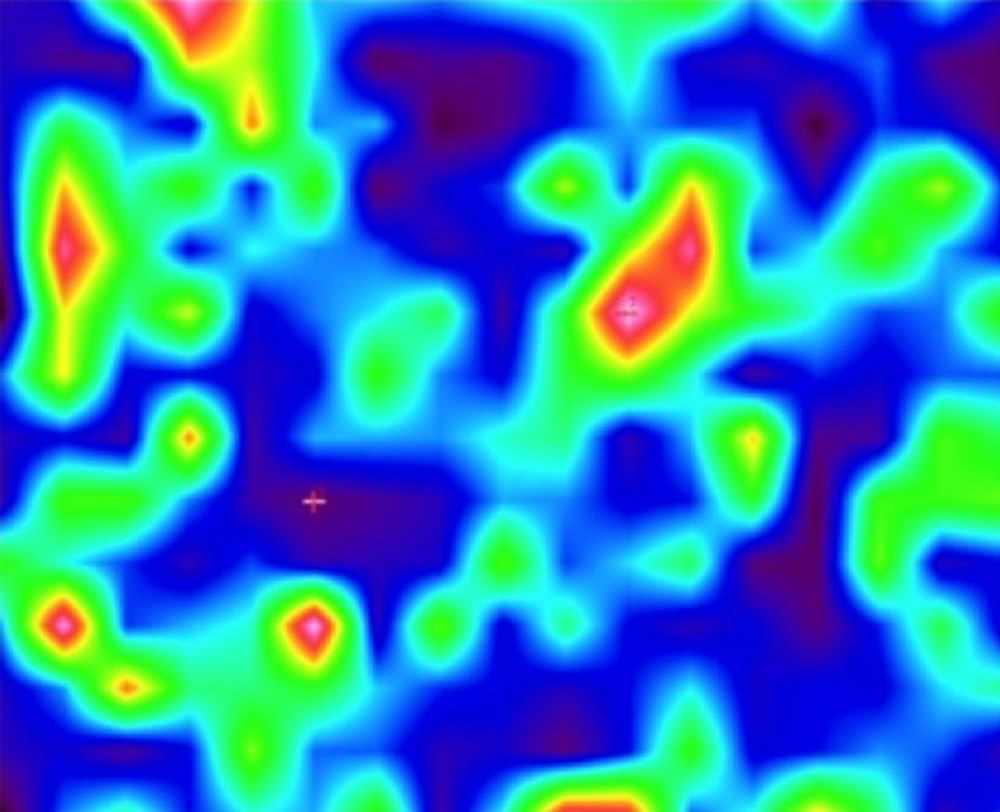

Hyperspectral Imaging

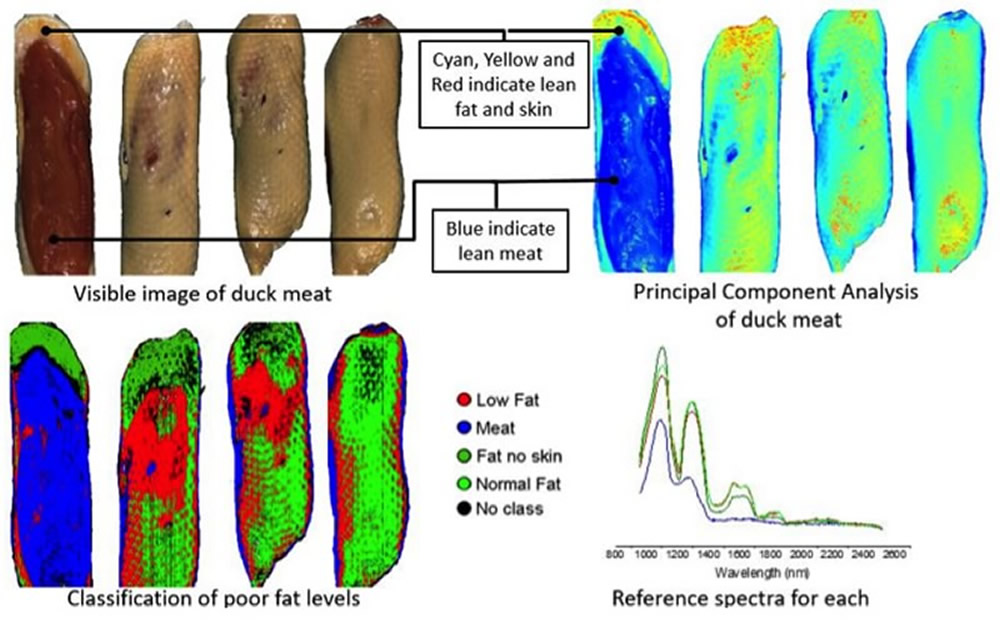

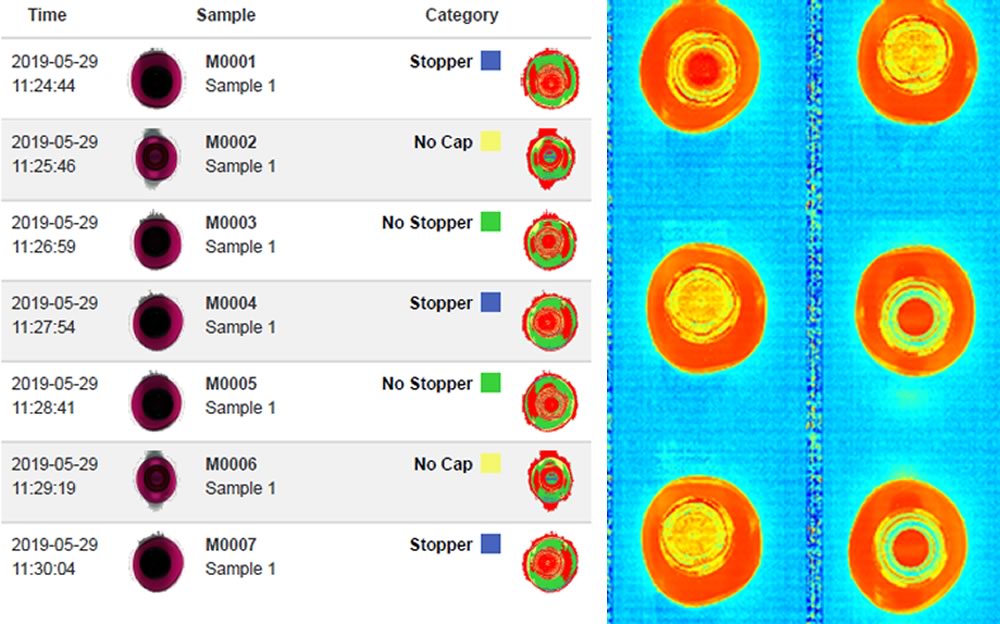

Hyperspectral imaging improves vision and discrimination power by using spectral signature information of surface materials, and it is one of the most promising techniques currently investigated for quality evaluation purposes. The main advantage of the hyperspectral imaging system is its ability to incorporate both spectroscopy and imaging information, not only to make direct assessment of different components simultaneously, but also to locate the spatial distribution of such components in the tested products. As the hyperspectral, imaging technique is a non-destructive tool it has been used more and more food applications and has applications in sectors such as pharmaceutical, medical device and photonics. Some of the applications hyperspectral imaging can be used for is remote sensing, machine vision, optical sorting, medical imaging, life science applications, spectroscopy instrumentation, automotive and transport, trace detection, biotechnology, precision agriculture, industrial monitoring, wood processing, sorting and security. Hyperspectral imaging in the food and beverage sector can offer food authentication and analysis across the sector but specifically in the areas of meat, fruit and vegetables, dairy products, grains, powders and seaweed. Such examples include analysing the percentage of fat or water content in food products, identifying defects, characterising product quality and locating contaminants.