Hyperspectral Imaging

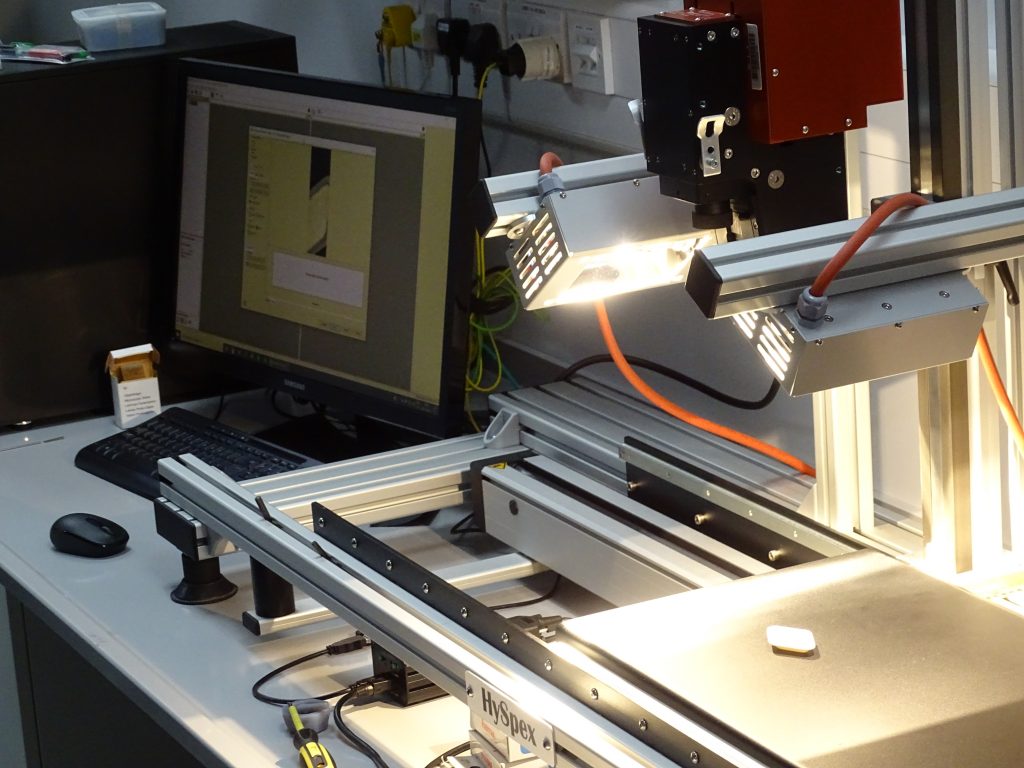

Figure 1: Typical Hyperspectral System

Hyperspectral imaging improves vision and discrimination power by using the surface spectral signature information of materials, and is one of the most promising techniques currently utilised for quality evaluation purposes. The main advantage of hyperspectral imaging is its ability to incorporate both spectroscopic and imaging information simultaneously, not only to make direct assessment of different components, but also to locate the spatial distribution of such components in tested products. Hyperspectral imaging is a non-destructive tool; therefore, it is being used more and more in food and beverage applications. In conjunction with hyperspectral imaging, principle component analysis (PCA) is the process of computing the principal components and using them to perform a change of basis on the spectral data. PCA is often used hand in hand with hyperspectral imaging. In the food and beverage industry, if there are two separate items to be identified, PCA can be used as a pre-processing technique for classification. Hyperspectral imaging research is important to the industry as it can be used for a wide variety of food and beverage types, and much of the research can be done without interfering with the product. If effective hyperspectral research is carried out, it can decrease the amount of products that are wasted due to not meeting quality standards. Hyperspectral imaging can be used for remote sensing, machine vision, optical sorting, medical imaging, life science applications, spectroscopy instrumentation, automotive and transport, trace detection, biotechnology, precision agriculture, industrial monitoring, wood processing, and secure sorting.

Hyperspectral Imaging in the Food and Beverage Industry

Hyperspectral imaging in the food and beverage sector can offer food authentication and analysis across the sector but specifically in areas of meat, fruit and vegetables, dairy products, grains, powders and seaweed. Such examples include:

- Analysing the percentage of fat or water content in food products

- Identifying defects

- Characterising product quality

- Locating contaminants

Hyperspectral imaging can be used for many varied in-line applications in food processing at distribution centres and has the potential to reduce waste e.g. it gives consumers the ability to view how far along in the ripeness process a product is and therefore enables them to better optimise distribution in accordance with ready-to-eat quality.

As food safety and quality are becoming more and more critical, hyperspectral imaging may be one of the new solutions that can help.

CAPPA Expertise

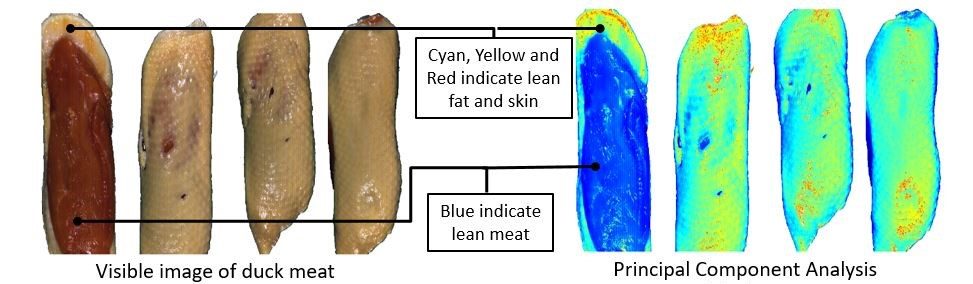

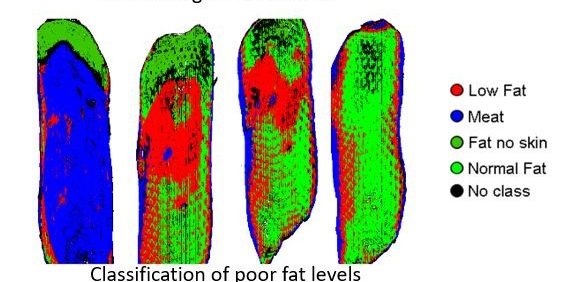

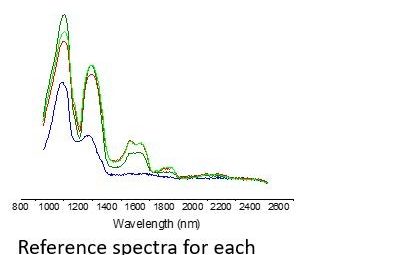

Classification of Fat Levels in Duck

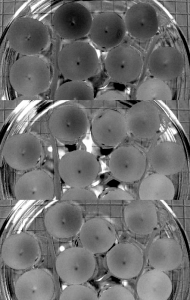

Since CAPPA first expanded its hyperspectral imaging capabilities, they have worked on a variety of different projects within the food and beverage industry. CAPPA has investigated the classification of fat levels in a variety of foods using hyperspectral imaging. One such capability involves the hyperspectral imaging of duck meat. In the below image, you can see the visible image of duck meat (2A) and the classification of low fat levels that can be seen when using the hyperspectral imaging system (2C). The principal component analysis (PCA) of the spectra is shown in Image 2B. PCA is used in exploratory data analysis and for making predictive models. The spectra used to determine the chemical information is shown in image 2D. Chemical imaging allows for quick quantitative analysis of foods during the manufacturing process and can help monitor and control the process. This enables the knowledge of product specialists to be applied in industrial level processes; ensuring high quality and efficient production. This capability would also work on a variety of meats and poultry including chicken, beef and pork.

2(A) 2(B)

2(C) 2(D)

Figure 2: Classification of Fat Levels in Duck

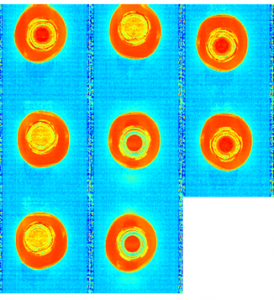

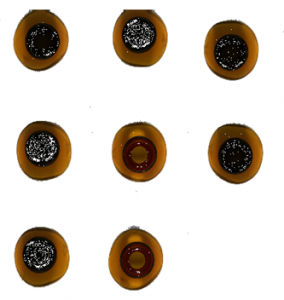

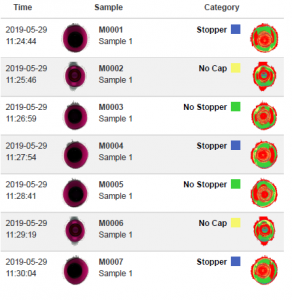

Short-Wave Infrared (SWIR) Investigation of Bottle Cap

CAPPA conducted hyperspectral short-wave infrared (SWIR) imaging of the below bottle caps. In this example, there is a rubber stopper under the cap. As a result, when the cap is on you cannot tell if the stopper is present or not. Using hyperspectral imaging you can determine if the rubber stopper is in place, without removing the cap and thus without interfering with the internal product. Figure 3A shows the first component of the principal component analysis performed on the SWIR images of the bottle sample. Figure 3B shows pseudo-RGB images of the bottle samples used to creating the classification model. Figure 3D shows the capped bottle without the stopper, Figure 3E is an example of the capped bottle with the stopper and Figure 3F is the bottle without cap or stopper. Figure 3C shows the results of the classification model. In each instance, the correct category was identified.

3A 3B 3C

3D 3E 3F

Figure 3: Short-Wave Infrared (SWIR) Investigation of Bottle Cap

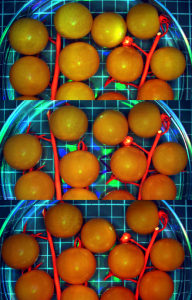

Ripeness of Tomatoes

A consumer would generally assess the ripeness of tomato fruit based on colour. From a commercial perspective, the grading, packing and processing of tomatoes requires automated systems with the ability to assess ripeness, and colorimetric methods are used to achieve this. The below Images 4A,B & C, show vine ripe tomatoes imaged over several days (top to bottom images were collected at day 1, day 4 and day 7 of the ripening study), with results from clustering (Image 4A) and PCA (Image 4B) of multispectral images taken of the tomato samples. Clustering analysis allows the distinction to be drawn between ripe and unripe tomatoes and the subsequent transition to ripeness. It may be seen from the cluster mapping of the images that there are 2 clusters specific to the tomatoes represented by a light shade and a dark shade that change, as time passes.

Image 4A – Clustering Image 4B – PCA Image 4C – LED imaging

Figure 4. Vine tomato ripening, with results from (A) clustering and (B) of multispectral images taken of tomato samples. The samples, from top to bottom in each image, are from day 1, day 4, and day 7 of the ripening study.

Peach Chill Injury

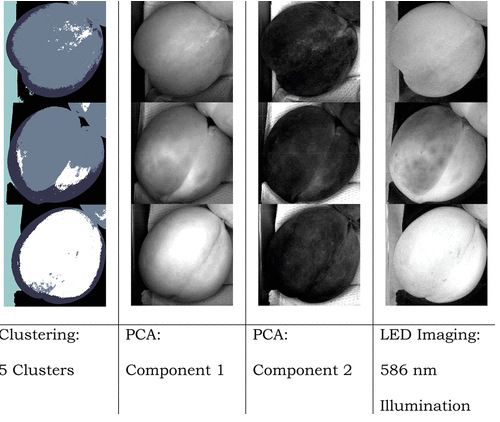

Many foods can become injured during transportation from farm to customer. Chill injury occurs in fruits when they are stored below optimal temperatures, causing damage to the fruit and reducing quality and shelf life. Multispectral imaging can be used to detect chill injury in fruits before it becomes visible to the naked eye. A study was conducted using the LED multispectral imager (MSI) to examine chill injury and its detection using a combination of multispectral imaging and multivariate analysis. Peaches were stored in a freezer for 1 and 24 h and were subsequently imaged along with peaches stored at room temperature. In Figure 5, the results from the cluster analysis and the first two components calculated using PCA are presented along with imaging of the samples using illumination from a 586 nm LED. In this instance, the illumination from the 586 nm LED produces an image that correlates with the findings from the multivariate analysis.

Figure 5. Peach chill injury, with results from clustering and PCA of multispectral images taken of peach samples. The samples, from top to bottom in each image, are from peaches with 24 h freezing, peaches with 1 h freezing, and reference sample peaches stored at room temperature.

CAPPA Equipment

The hyperspectral imaging system at CAPPA incorporates a spectral camera, HySpex SWIR – 384, with several lenses mounted on a translation stage, combined with a focused broadband illumination source. The camera has a state of the art Mercury Cadmium Telluride (MCT) sensor with cooling down to 150K which yields low background noise, high dynamic range and exceptional signal to noise (SNR) levels, making it ideal for use in the food and beverage industry.

CAPPA also has a visible hyperspectral-imaging camera, HySpex VNIR – 3000 N, with a pixel size of 3.45 μm. With 3000 spatial pixels, 600 bands and a noise floor of 2.4e- it will provide outstanding SNR levels in dark environments. The visible region is particularly suited to coloured samples typically found in the food and agriculture industry.

You can see some of the previous work CAPPA has conducted in the food and beverage industry here, additional research on the ripeness of tomato and peach chill injury here. If you would like to learn more about the hyperspectral imaging capabilities available, you can contact CAPPA directly here.